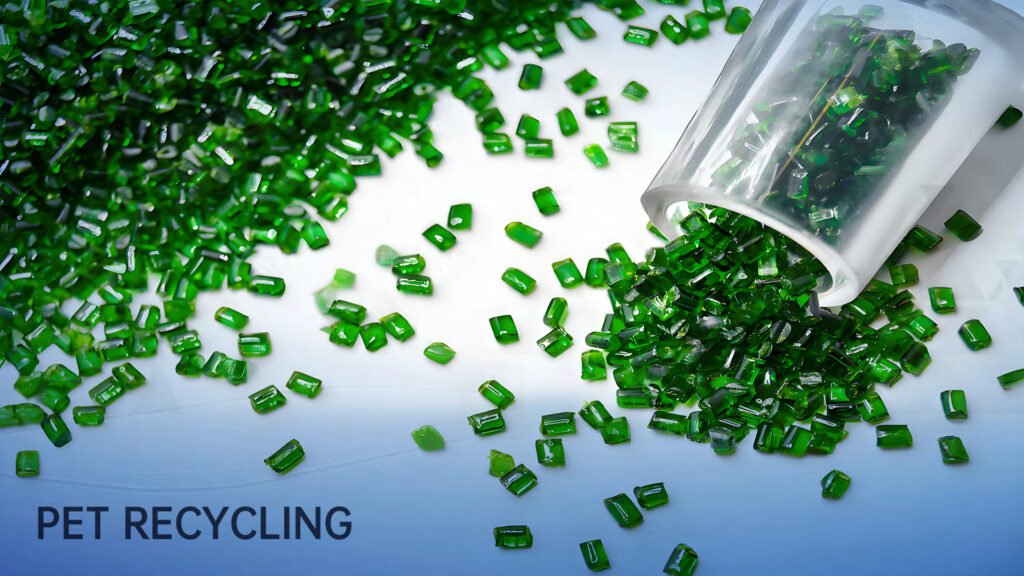

PET Recycling and Pelletizing is the process of converting waste polyethylene terephthalate (PET – commonly found in beverage bottles, packaging materials, PET sheets/films, PET waste fibers, polyester waste fabric) into recycled plastic pellets through physical or chemical methods. This technology serves as the core process for PET circularity, offering both environmental and economic value.

Core Process Stages:

Pre-treatment:

- Sorting: Manual or mechanical removal of contaminants (caps, labels, etc.).

- Shredding/Crushing: Washed bottles are shredded into “flakes”.

- Deep Cleaning: Removal of residual contaminants through floatation separation and friction washing.

Melting and Pelletizing:

- Flakes are melted at high temperatures (270–290°C) and plasticized in a screw extruder.

- The melt is filtered through fine screens to remove impurities and extruded as strands through a die head.

- A pelletizer cuts the cooled strands into uniform pellets (3–5mm). [Note: The text specifies underwater pelletizing is used.

Post-treatment:

- Crystallization and Drying: Removes moisture and increases pellet crystallinity to prevent hydrolysis during subsequent processing.

- Viscosity Enhancement (Optional): Increases intrinsic viscosity via Solid-State Polycondensation (SSP) to meet high-end requirements (e.g., food-grade).

Value Proposition:

- Environmental Waste Reduction: Reduces petroleum consumption, landfill pollution, and carbon emissions.

- Resource Circulation: Recycled pellets can be spun into polyester fiber (for clothing, carpets) or injection-molded into packaging and consumer goods.

- Economic Viability: Recycled PET (rPET) costs less than virgin material, with markets expanding under policy incentives.

Technical Challenges lie in impurity control and viscosity stability, requiring efficient sorting, deep cleaning, and advanced modification processes. The development of chemical recycling (depolymerization regeneration) technologies promises further improvements in PET recovery rates and quality.

Addition from last sentence: PET recycling pelletizing utilizes twin-screw extruders combined with underwater pelletizing to effectively prevent PET degradation during melt extrusion, thereby ensuring viscosity stability.

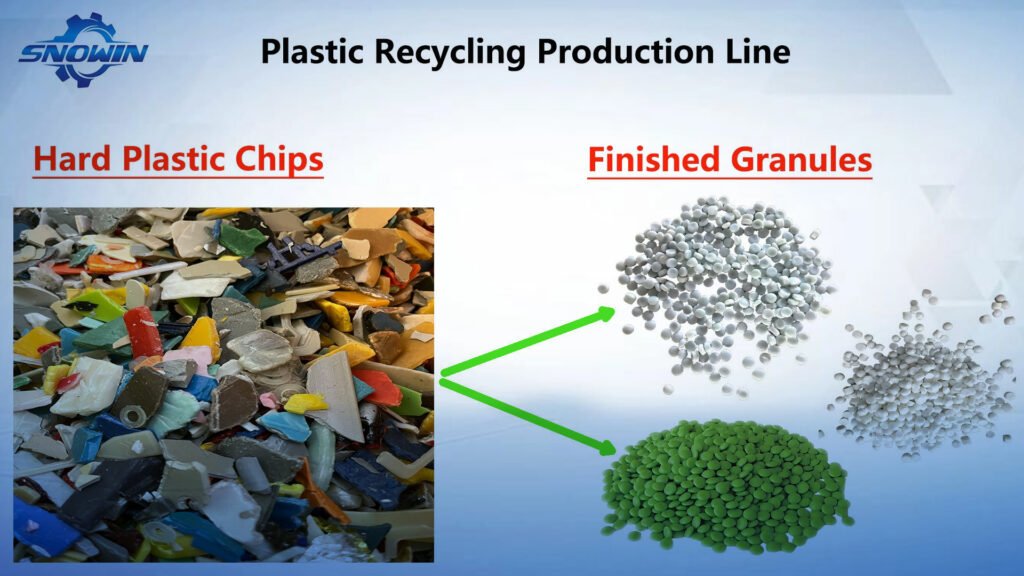

Hard plastic scraps recycling and pelletizing is a highly common and crucial plastic recycling technology. It effectively reduces raw material waste, lowers production costs, and lessens environmental burdens. The recycling process is as follows:

- Collection and Sorting:

Sources: Collect runner scrap (sprue), flash, rejects, trial-run materials, etc., generated by injection molding machines.

Crucial Step: Rigorous sorting is key to success! Scrap must be separated by plastic type (e.g., PP, ABS, PC, PS, PE) and color. Mixing different plastic types severely compromises the performance of the recycled material and the quality of the final product. Simultaneously, remove other contaminants like metal, labels, rubber, etc.

- Shredding/Grinding:

Purpose: Break down large scrap pieces into smaller, uniform fragments or flakes (commonly called “shreds” or “flakes”).

Equipment: Plastic shredders/grinders are used.

Key Points: Select appropriate shredder blades and screen mesh size to control fragment size (typically 3mm-12mm) for subsequent washing, drying, and pelletizing.

- Washing and Drying:

Washing: Necessary if scrap is contaminated with oil, mold release agents, dust, etc. Common methods include:

Friction Washers: Remove surface dirt through friction between fragments and water.

Rinsing/Spray Washing: Flushing with clean water.

(Optional) Detergent Washing: For stubborn oil/grease.

Dewatering: After washing, fragments contain significant water; use centrifugal dryers/dewaterers to remove most free water.

Drying: Critical! Residual moisture causes bubbles during high-temperature pelletizing, affecting pellet quality and potentially damaging equipment. Common equipment:

- Hot Air Dryers: Most commonly used.

Desiccant Dryers: More effective for hygroscopic plastics (e.g., PET, PA, PC), thoroughly removing moisture.

Key Points: Ensure fragments are completely dry (moisture content typically required below 0.1%).

Melting, Extrusion, and Filtration:

Core Equipment: Plastic extrusion pelletizing line (single-screw or twin-screw extruder).

Process: Dried shreds are fed into the extruder via a hopper. Under the action of screw rotation (conveying, shearing) and barrel heating, the plastic melts into a viscous flow.

- Critical Step – Filtration:

Purpose: Remove tiny unmelted impurities, carbonized material, metal fines, etc., from the melt to ensure pellet purity and subsequent processing performance.

Equipment: Screen changers (manual, hydraulic automatic, continuous rotary) with filter screens (multiple layers of different mesh sizes).

Key Points: Select filter mesh size (e.g., 40, 60, 80, 120 mesh or higher) based on feedstock cleanliness and required pellet purity. Finer mesh provides better filtration but increases screen change frequency/resistance.

- Pelletizing:

The molten plastic is extruded through a die into strands and cut into pellets.

Cooling Methods:

Water-Cooling Strand Pelletizing: Strands are hardened by passing through a water bath, then cut into cylindrical pellets by a pelletizer. This is the most common method, offering simple equipment and low cost.

Air-Cooling Die-Face Hot Pelletizing: Rotating knives at the die face cut the melt immediately upon extrusion; pellets are cooled by air. Suitable for heat-sensitive, sticky materials, or when high output and more uniform pellets are needed. Pellets are typically spherical or lentil-shaped.

Underwater Pelletizing: Cutting knives operate within a sealed water chamber; melt is cut upon extrusion and instantly quenched by water. Suitable for high-viscosity, sticky materials (e.g., TPE, TPU, highly filled compounds) and applications demanding high pellet appearance. Pellets are typically spherical with a smooth surface.

- Cooling, De-watering/Drying, and Screening:

Cooling: Ensure pellets are fully cooled and solidified (often requires further cooling after water or air cooling).

De-watering/Drying: For water-cooled or underwater pellets, centrifugal dryers/dewaterers remove surface moisture.

Drying: If necessary (especially for hygroscopic materials or stringent downstream requirements), perform low-temperature hot air drying.

Screening: Use vibrating screens to remove oversized/undersized pellets, fused pellets (“tails”), and powder, ensuring uniform pellet size.

- Packaging and Storage:

Qualified pellets are packaged (typically in woven bags or bulk bags) by type and batch.

Store in a dry, clean environment to prevent moisture absorption and contamination.