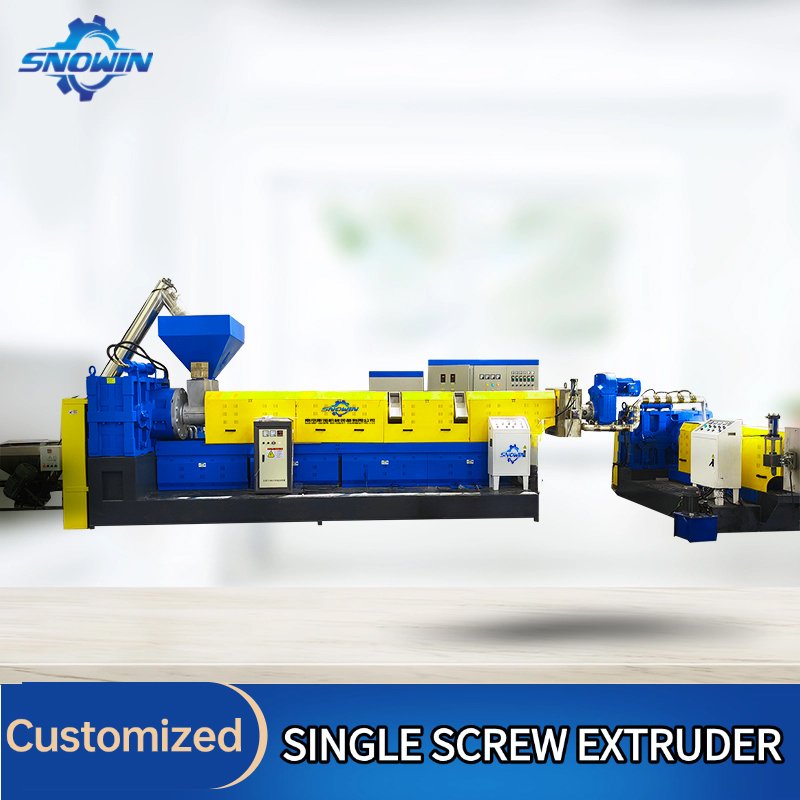

SINGLE SCREW EXTRUDER

In the battle against white pollution and resource depletion, single screw waste plastic recycling and granulating technology acts like a sophisticated “renaissance factory,” quietly transforming the fate of waste materials. It incorporates discarded fragments from industrial corners, production plastic scraps/chips/flakes, crumpled waste films, and even tough discarded woven bags (usually made of polypropylene/ polyethylene) into its transformation process. These seemingly useless plastics first undergo thorough shredding, washing, and drying, metamorphosing into clean fragments. Subsequently, under the intense heat and shearing forces within the single-screw extruder, the fragments melt and plasticize, with impurities being further filtered out. Finally, the molten plastic is extruded through a die head and cut into uniform, plump recycled plastic pellets.

These recycled/regrind pellets, pure in color and stable in performance, can be reintroduced into production lines to become pipes, containers, daily necessities, or even industrial components. This circular chain significantly alleviates the pressure on landfills and incineration, reduces the demand for virgin petroleum resources, and, moreover, endows waste with economic value. It paves a solid road towards a green future characterized by “Reduce, Reuse, Recycle” (the 3Rs). Every single recycled pellet stands as a silent guardian of our planet.

| Model | Diameter (mm) |

L/D | Motor Power (kW) |

Speed (rpm) |

Capacity (kg/h) |

|---|---|---|---|---|---|

| SJ-100 | 100 | 20-35 | 45-55 | Max.120 | 100-150 |

| SJ-120 | 120 | 20-35 | 55-75 | Max.120 | 100-200 |

| SJ-150 | 150 | 20-35 | 75-90 | Max.120 | 200-300 |

| SJ-180 | 180 | 20-35 | 110-160 | Max.120 | 400-600 |

| SJ-200 | 200 | 20-35 | 160-280 | Max.120 | 700-900 |

| SJS-100/100 | 100 | 20-35 | 45-55 | Max.120 | 100-200 |

| 100 | 7-20 | 30-37 | |||

| SJS-120/120 | 120 | 20-35 | 55-75 | Max.120 | 200-300 |

| 120 | 7-20 | 37-45 | |||

| SJS-150/150 | 150 | 20-35 | 75-90 | Max.120 | 200-400 |

| 150 | 7-20 | 45-55 | |||

| SJS-180/180 | 180 | 20-35 | 110-160 | Max.120 | 450-800 |

| 180 | 7-20 | 75-90 |