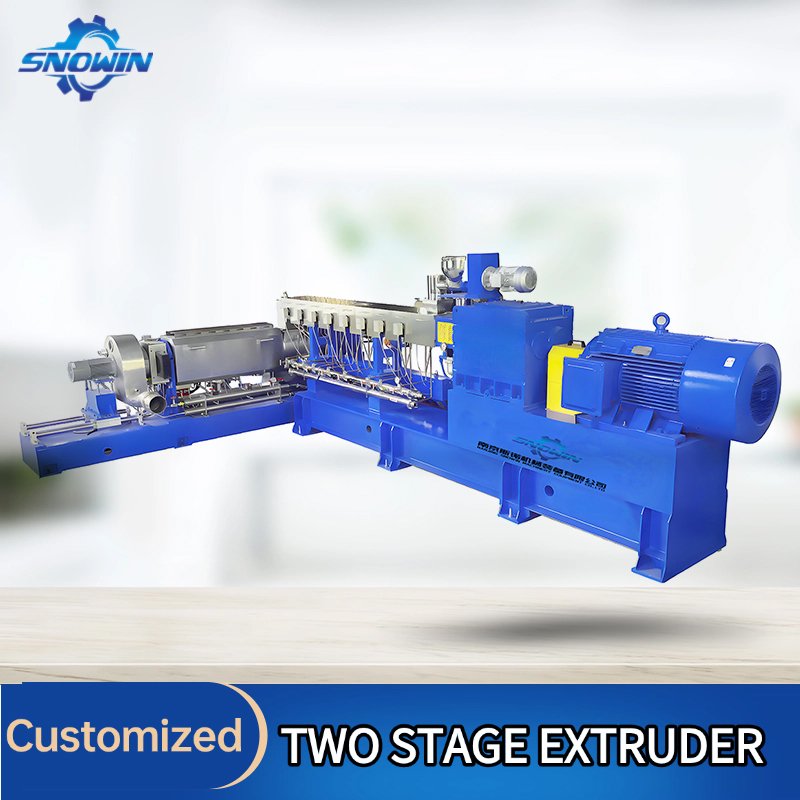

TWO STAGE SCREW EXTRUDER

The two stage extruders feature a unique two-stage design comprising an upper-stage co-rotating twin screw extruder connected in series with a lower-stage single screw extruder. This precise division of the two-stage process overcomes the technical limitations of conventional equipment when processing heat-sensitive and highly-filled materials.

Upper Stage: Twin Screw Extruder – Efficient Compounding & Gentle Plastication

The twin screw segment excels in powerful compounding and initial plastication:

- Achieves nanoscale homogenization of stabilizers and plasticizers in PVC cable compounds, ensuring consistent insulation properties.

- Processes heat-sensitive materials (e.g., TPU, bio-based plastics) with low shear and high heat transfer efficiency, preventing localized overheating and degradation.

- Efficiently deagglomerates carbon black clusters in 60%-80% high-concentration black masterbatches, overcoming dispersion challenges.

- Rapidly wets and incorporates inorganic phases (e.g., calcium carbonate fillers) into the resin matrix for masterbatches with >70% filler loading, using powerful intermeshing elements.

Lower Stage: Single Screw Extruder – Stable Pressure Build-up & Precision Extrusion

The single-screw segment handles melt homogenization and pressure control:

- Utilizes a deep-channel gradual compression section to further eliminate bubbles and enhance the density of PVC cable compounds.

- Achieves ultra-low-pulse stable extrusion (often aided by a melt gear pump), ensuring no stagnation in flow paths for heat-sensitive materials.

- Provides gentle compaction for highly-filled systems, preventing structural damage to fillers caused by excessive shear.

- Ensures smooth, defect-free pellet surfaces through high-precision die head temperature control.

The tandem design successfully separates the “mixing/dispersing” function from the “extrusion/shaping” function. This endows the system with the process flexibility of twin-screw extruders and the extrusion stability of single-screw extruders.Its outstanding performance in:

- Significantly improving the temperature resistance of PVC cable compounds

- Reducing scrap rates for heat-sensitive materials

- Ensuring the tinting strength of high-concentration masterbatches

- Achieving high filler loading with low wear in calcium carbonate masterbatches

has established this technology as a core driving force in the advancement of specialty materials. It not only breaks through the limitations of traditional processes but also propels industries like cable, new energy, and packaging towards higher performance, lower cost, and enhanced sustainability.

| Model | Diameter (mm) |

L/D | Motor Power (kW) |

Speed (rpm) |

Capacity (kg/h) |

|---|---|---|---|---|---|

| SNS-50/120 | 50.5 | 32-48 | 45-90 | Max.600 | 100-250 |

| 120 | 7-15 | 30-37 | Max.70 | ||

| SNS-65/150 | 62.4 | 32-48 | 90-160 | Max.600 | 200-450 |

| 150 | 7-15 | 35-55 | Max.70 | ||

| SNS-75/180 | 71 | 32-48 | 132-250 | Max.600 | 400-800 |

| 180 | 7-15 | 45-75 | Max.70 | ||

| SNS-95/200 | 93 | 32-48 | 315-450 | Max.600 | 800-1200 |

| 200 | 7-15 | 75-110 | Max.70 |