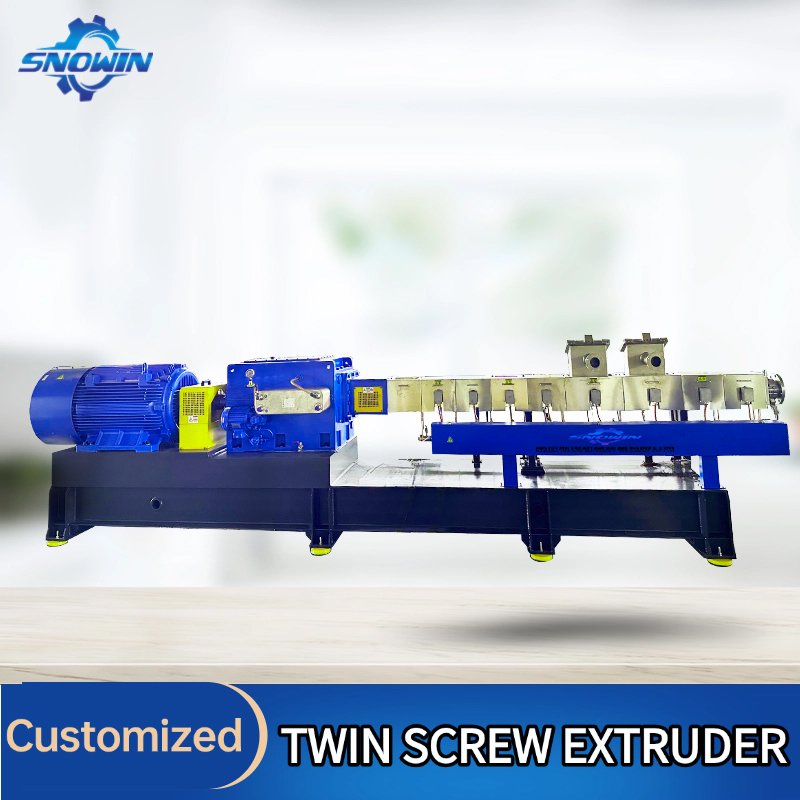

SN SERIES TWIN SCREW EXTRUDER

Nanjing SNOWIN: Powering Material Innovation, Leading Efficient Production

In the field of plastic modification and high-performance material preparation, SNOWIN leverages its years of project experience, R&D, and manufacturing capabilities to specialize in providing a complete range of industrial-grade co-rotating twin screw extrusion solutions. The company’s core product line covers a wide spectrum of models with screw diameters ranging from 20mm to 95mm, precisely matching the full spectrum of needs from pilot-scale R&D and pilot-scale verification to large-scale industrial production.

For the initial R&D phase: SNOWIN’s smaller extruders (e.g., 20-40mm) serve as the ideal platform in laboratories for exploring new formulations and optimizing process parameters. They enable rapid feasibility verification with minimal material cost.

For the pilot-scale stage: Models (e.g., 50-75mm) provide higher processing capacity and stability, offering reliable support for process scale-up and sample preparation, effectively mitigating industrialization risks.

For large-scale continuous production: Sinuo’s high-capacity extruders (e.g., 95mm and above) demonstrate exceptional stability and efficiency, meeting the massive market demand for high-quality modified plastic pellets.

SNOWIN’s extruders act as a versatile processing platform for producing diverse plastic pellets. They are widely applied in:

Plastic Modification: Enhancing properties of base resins such as toughness, heat resistance, and flame retardancy.

Plastic Filling: Efficiently dispersing fillers like calcium carbonate or talc to reduce costs and improve specific properties.

Reinforced Composites: Achieving uniform dispersion and excellent wetting of glass fibers (GF) or carbon fibers (CF) within the resin matrix to produce high-strength, high-modulus reinforced pellets.

Masterbatches: Ensuring ultra-high dispersion and coloring stability of pigments or dyes within the carrier resin.

Other complex processes: Such as reactive extrusion, polymer alloying, devolatilization, and pelletizing.

Committed to its full-scale, multi-capacity extrusion equipment system and extensive technical expertise, Nanjing Sinuo provides global customers with efficient and reliable equipment support transforming laboratory concepts into scaled production. The company strives to be a core force driving advancements in material science and technology and promoting industrial upgrading.

| Model | Diameter (mm) |

L/D | Motor Power (kW) |

Torque Grade (T/A³) |

Capacity (kg/h) |

|---|---|---|---|---|---|

| SN-35 | 35.6 | 40-68 | 18.5-37 | 6.8-11 | 10-150 |

| SN-40 | 41.1 | 40-68 | 37-55 | 6.8-11 | 100-250 |

| SN-50 | 50.5 | 40-68 | 45-90 | 6.8-11 | 100-300 |

| SN-52 | 51.4 | 40-68 | 75-110 | 6.8-11 | 200-350 |

| SN-65 | 62.4 | 40-68 | 90-160 | 6.8-11 | 250-400 |

| SN-75 | 71 | 40-68 | 132-250 | 6.8-11 | 500-800 |

| SN-85 | 81 | 40-68 | 280-355 | 6.8-11 | 1000-1500 |

| SN-95 | 93 | 40-68 | 315-450 | 6.8-11 | 1000-2000 |